Get in touch

Products

Industrial MESH SUPPLIES IN JOHANNESBURG, GAUTENG

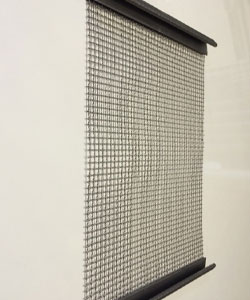

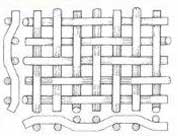

WOVEN WIRE MESH

Woven wire mesh is a woven fabric made of metallic material, flexible enough to be woven into a variety of shapes and sizes. At Industrial Mesh Supplies we offer a variety of products, including specialized high quality woven wire cloths of different styles, as well as custom requirements made to your specifications. Woven wire mesh can be supplied in rolls of various widths and lengths.

This is used extensively in various industries and different applications. All materials are woven from wire, and are available ex-Stock from 30mm to 25 Micron, in various types of weave. These meshes can also be punched in various diameters or shapes, and spot-welded together to create screen packs.

Specifications Required To Order

*Mesh or Aperture size

*Wire Mesh diameter

*Type of material

*Length & Width

*Flat or with “hooks”

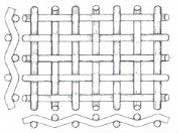

Plain Weave

Most commonly used weave. Each weft wire passes alternatively over and under each warm wire and vice versa. Warp and weft wire diameters are generally the same. Plain weave meshes are available with apertures from 10.7mm (2 mesh) to 0.05mm (325 mesh).

| Mesh Count per inch | Wire Dia. (mm) | Aperture Size (mm) | Open Area | Weight for Stainless Steel (kg/sq m) |

| 5 | 1.000 | 4.080 | 65% | 2.48 |

| 6 | 0.900 | 3.333 | 62% | 2.41 |

| 8 | 0.900 | 2.275 | 51% | 3.22 |

| 8 | 0.710 | 2.465 | 60% | 2.00 |

| 10 | 0.900 | 1.640 | 42% | 4.02 |

| 10 | 0.710 | 1.830 | 52% | 2.50 |

| 10 | 0.500 | 2.040 | 65% | 1.24 |

| 12 | 0.560 | 1.557 | 54% | 1.87 |

| 14 | 0.560 | 1.254 | 48% | 2.18 |

| 16 | 0.560 | 1.028 | 42% | 2.48 |

| 16 | 0.500 | 1.088 | 47% | 1.99 |

| 16 | 0.450 | 1.138 | 51% | 1.61 |

| 16 | 0.315 | 1.273 | 64% | 0.79 |

| 20 | 0.500 | 0.770 | 37% | 2.48 |

| 20 | 0.450 | 0.820 | 42% | 2.01 |

| 20 | 0.355 | 0.915 | 52% | 1.25 |

| 24 | 0.355 | 0.703 | 44% | 1.50 |

| 28 | 0.315 | 0.592 | 43% | 1.38 |

| 30 | 0.315 | 0.532 | 39% | 1.48 |

| 30 | 0.280 | 0.567 | 45% | 1.17 |

| 36 | 0.250 | 0.456 | 42% | 1.12 |

| 40 | 0.224 | 0.411 | 42% | 1.00 |

| 50 | 0.210 | 0.298 | 34% | 1.10 |

| 50 | 0.190 | 0.318 | 39% | 0.90 |

| 60 | 0.200 | 0.22 | 28% | 1.23 |

| 60 | 0180 | 0.243 | 33% | 0.97 |

| 70 | 0.150 | 0.231 | 34% | 0.78 |

| 80 | 0.125 | 0.193 | 37% | 0.62 |

| 100 | 0.112 | 0.142 | 31% | 0.62 |

| 120 | 0.090 | 0.122 | 33% | 0.48 |

| 120 | 0.080 | 0.132 | 39% | 0.38 |

| 150 | 0.060 | 0.109 | 42% | 0.27 |

| 165 | 0.050 | 0.104 | 46% | 0.20 |

| 180 | 0.050 | 0.091 | 42% | 0.22 |

| 200 | 0.050 | 0.077 | 37% | 0.25 |

| 200 | 0.040 | 0.087 | 47% | 0.16 |

| 250 | 0.040 | 0.062 | 37% | 0.20 |

| 300 | 0.036 | 0.055 | 42% | 0.13 |

| 325 | 0.036 | 0.042 | 29% | 0.21 |

| 400 | 0.028 | 0.035 | 28% | 0.18 |

| 500 | 0.025 | 0.026 | 26% | 0.16 |

Hollander Weave

A Palin Weave with the wrap wires of larger diameter than the weft. The weave is made up of a limited number of wrap wires interwoven with the maximum number of weft which can be knocked up. This cloth is strong and firm and is most frequently used for high pressure filtration.

| Nominal Mesh Count per Inch | Wire Diameter | Particle Retention (micron) | Porosity | Thickness (mm) | Weight for Stainless Steel (kg/sq.m) |

| warp 12 weft 70 | warp 0.600 weft 0.400 | 300 | 62% | 0.225 | 3.64 |

| warp 24 weft 110 | warp 0.355 weft 0.250 | 120 | 60% | 0.710 | 2.70 |

| warp 50 weft 250 | warp 0.140 weft 0.112 | 60 | 59% | 0.315 | 1.00 |

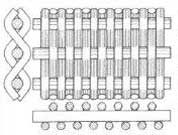

Twill Weave

Stronger than Plain Weave. Each weft wire alternatively crosses over two, then under two warp wires, producing a diagonal pattern. The wire diameter for both warp and weft is normally the same. Twill weave is usually used to accommodate heavier than standard wire diameter in association with a given mesh. Specifications finer than 300 are normally twill woven.

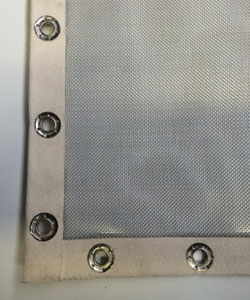

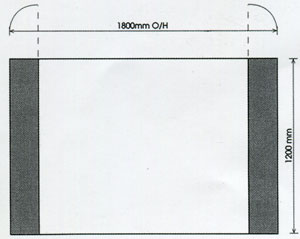

Heavy Wire Mesh

This is a manual process of weaving to suit various applications, wire diameters range from a 0.9mm to a 20mm, and are mostly made up to customers specifications. These screens can also be supplied with “hooks” or metal edges.

Specifications required to order

*Aperture

*Wire Diameter

*Type of Material

*Length & Width

*Flat or with hooks 1200mm x 1800 O/H

eg. 25mm Ap x 8mmØ

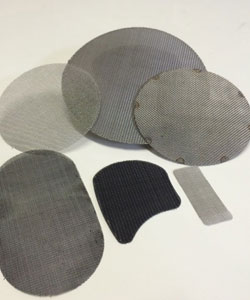

Punched Discs / Screen Packs

These meshes can also be punched to various diameters or shapes, and spotwelded together to make screen packs. Our standard Disc range is from 23mm to 305mm diameter, maximum wire thickness to be punched is 0.7mm.

Specifications Required to order

*Diameter

*Mesh or micron size

*If spotwelded, mesh sequence

*Quantity

Additional Tensioning Methods

Additional tensioning methods can be manufactured to your specific requirements.